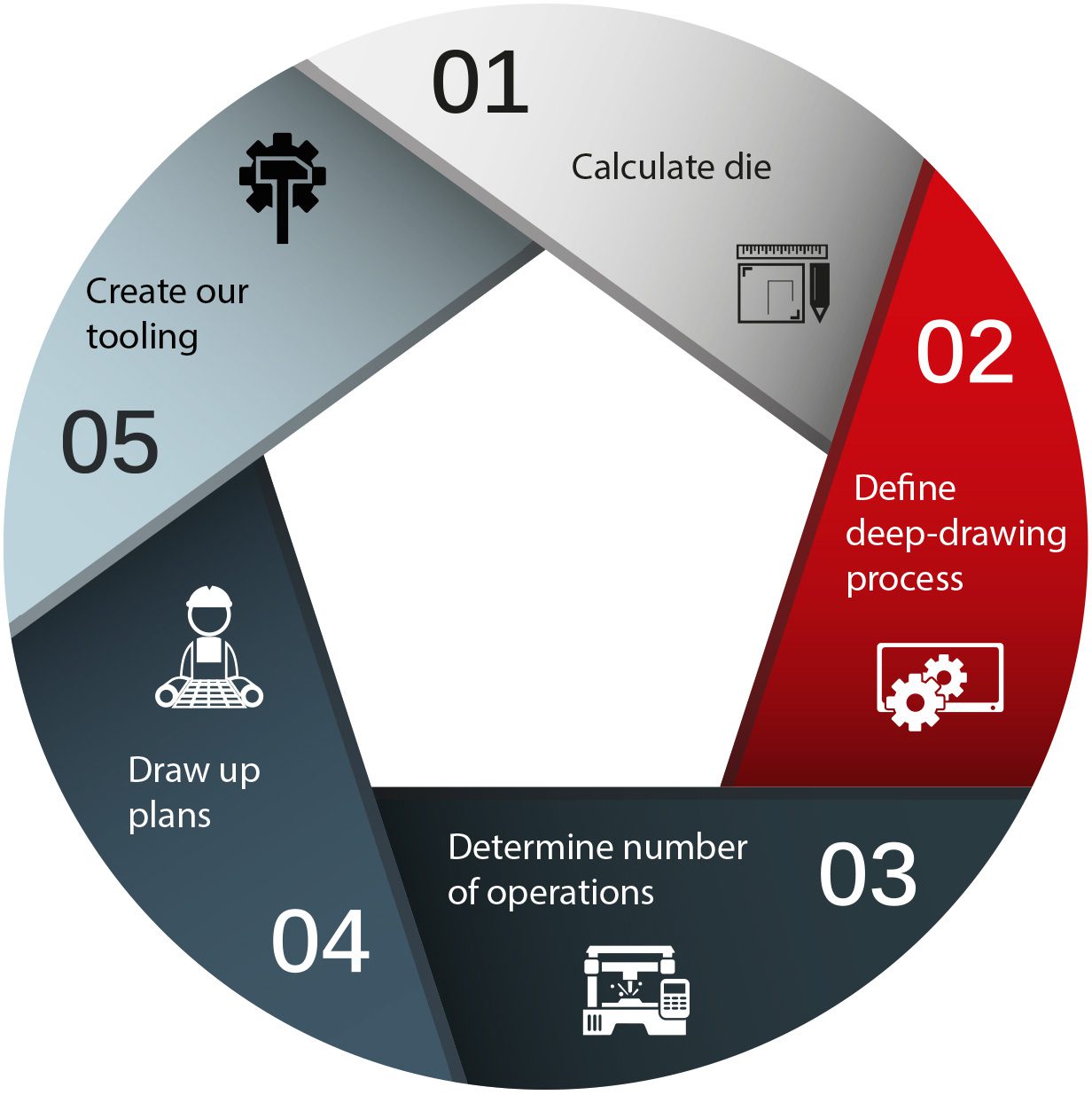

Research and development department

Emprotec brings its expertise right from the design stage

With more than 35 years experience in deep drawing, Emprotec can, of course, work from a given plan, but can also assist your research and development department in designing parts at the pre-production phase to adapt them to the process and specific requirements of the deep drawing, in order to optimise the costs of tooling and production. With this perspective, our research and development team works with our in-house tooling workshop to design and create the tools which correspond best to the technical requirements of a given part.

Tooling

Tooling created in-house to ensure reliable and secure production.

In order to meet the demands of our clients and the delivery deadlines, Emprotec creates its own transfer tools, taking into account the need to change tools quickly, resulting in standardization in particular in maintaining a regular height of the tooling.

Aware of the need to optimize costs, Emprotec also creates tooling which allows several operations to take place at the same time.

The advantage of having an in-house tooling workshop is that any damaged tooling can be repaired and returned to production rapidly. Moreover this allows us to adapt existing tooling to any changes required by the client.

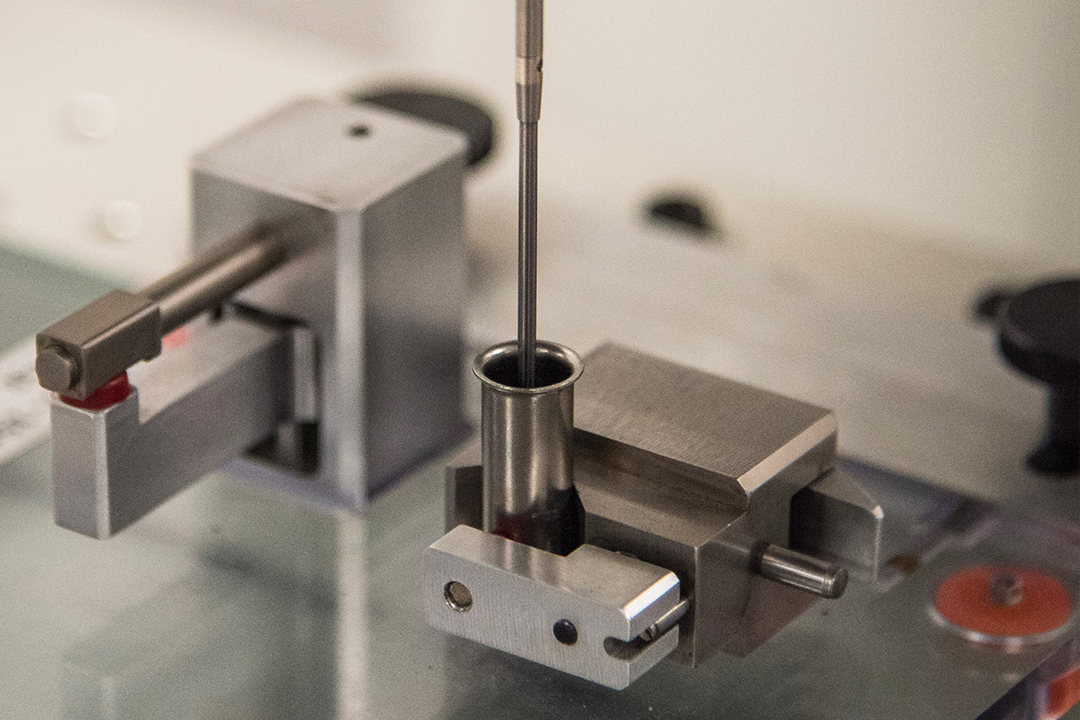

Tooling may be very well designed and created but it is always necessary to carry out manual finishing. This stage consists of placing a blank (sheet of metal) into the tool in order to check the places where it breaks, rubs or slips too easily.

In order to guarantee that the metal can pass correctly the tooling is finished manually which requires great skill, guaranteed by the experience of Emprotec’s team.

After making the tooling our integrated workshop also carries out the maintenance, this allows us to ensure that it lasts without altering its characteristics and its quality.

Production

Deep drawing allows considerable shaping of material to produce parts of low thickness (0.3 to 2 mm) and great depth (up to 65mm).

Their shaping can be carried out by progressive tooling or by transfer press. The latter is the technique used by Emprotec. It is true that production by transfer press presents numerous advantages especially in terms of cost and flexibility. A single press is required to carry out all the procedure of deep drawing and it is possible to adapt a part without create new tooling.

Emprotec’s machinery consists of 9 transfer presses of 60 to 200 tonnes and 3 swan neck presses of 15 and 150 tonnes which make a production capacity of up to 1 million parts.

Areas of intervention

Emprotec is able to meet the specific needs of international markets effectively and exports nearly 70% its production.

The company offers flexible logistic solutions and invests in developing reliable distribution networks: rapid deliveries, tracking deliveries in real time, personalised solutions for stock management to adapt to fluctuations in demand.

Emprotec works to establish trusting long term relations with its clients based abroad.

For more than 30 years Emprotec has produced a variety of tailor-made parts for sectors of industry such as automotive, aeronautic, aerospace, energy, construction.

Quality

Right from the beginning, when the company was founded, Emprotec’s managers placed quality at the centre of customer relations. In the course of time this constant focus has been formalised when the company obtained IS0 9001 certificate in 2008.

In 2016 Emprotec improved its quality management system to comply with the demands of the 2015 version of this standard.

In addition to the guarantee that this certification brings, our teams are careful in respecting the range of controls defined by the client. At the very least, systematic controls of samples are carried out on all our productions. These controls may be reinforced according to your needs and specifications.

Means of production

3D measuring machines

CAC/CAO software

(SolidWorks)

9 transfer presses

(60 to 200 T)

3 swan neck presses

(15 to 150 T)

Traditional machining

and CNC tools (CN)

Deburrer, dryer

Metrology

Would you like

to learn more?

Your trusted partner in deep drawing, Emprotec supplies you with high quality technical parts, bringing together expertise, innovation and meeting clients’ demands.

Parc d’activités Alpespace

401 Voie Galilée

73800 Sainte-Hélène-du-Lac

France

Regional Support: