Who are we?

Founded in 1988 and based in Savoie (France) Emprotec specialises in producing technical parts using deep drawing.

Our transfer presses, in a workshop of over 1000 m2 , enable us to produce complex parts in medium and long machine runs. We design, produce and maintain our own transfer tools to give you the guarantee of reliable and secure production.

Our team accompanies you at each stage of your project: from designing in our in-house R & D department to post-production quality control.

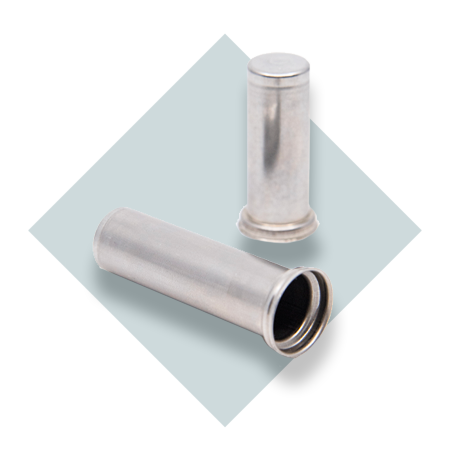

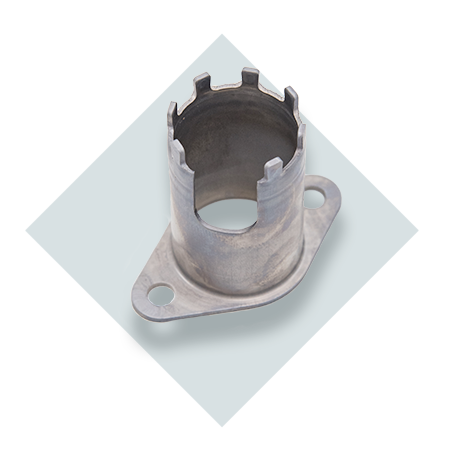

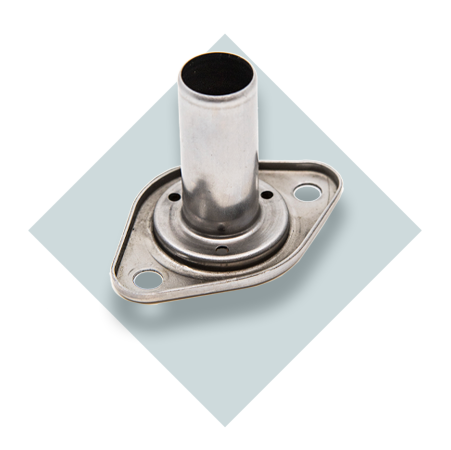

Technical parts

With deep-drawing technique it is possible to produce a great variety of technical and tailor-made parts in a wide range of materials: stainless steel, soft steel, aluminium, copper, zinc, brass….

Emprotec has been a specialist in this technology for over 30 years. Therefore Emprotec will offer you the best technical solution to meet your functional specifications while respecting your requirements in terms of cost. The only constraint: that the part can fit under the press.

Deep drawing

Emprotec shapes parts by cold deep drawing of sheet metal. This type of shaping is carried out on a transfer press fitted with a deep drawing tool which we design at the in-house workshop.

This technique presents many advantages both in terms of cost and in quality of parts, in particular, thanks to the wide range of materials which can be transformed and the very nature of the process, which allows a high degree of flexibility in allowing a part to be modified without requiring a completely new tool.

Commitments

With a high level of technical skill, a creative mindset, an innovative and effective production process, for over 30 years Emprotec has put the skill of its teams, the quality of its products and partnerships with its clients at the heart of the company’s development. It cultivates strong values: respect, confidence, precision and team spirit.

Advice and assistance

From designing the parts to reducing costs and offering alternatives to other processes

Design and development

In-house tooling for greater reliability and safeguard of production

Flexibility and quick responses

A polyvalent team of 9 people

Adaptability of the company

Which, thanks to its close organisation, is able to adapt and offer fast and effective solutions

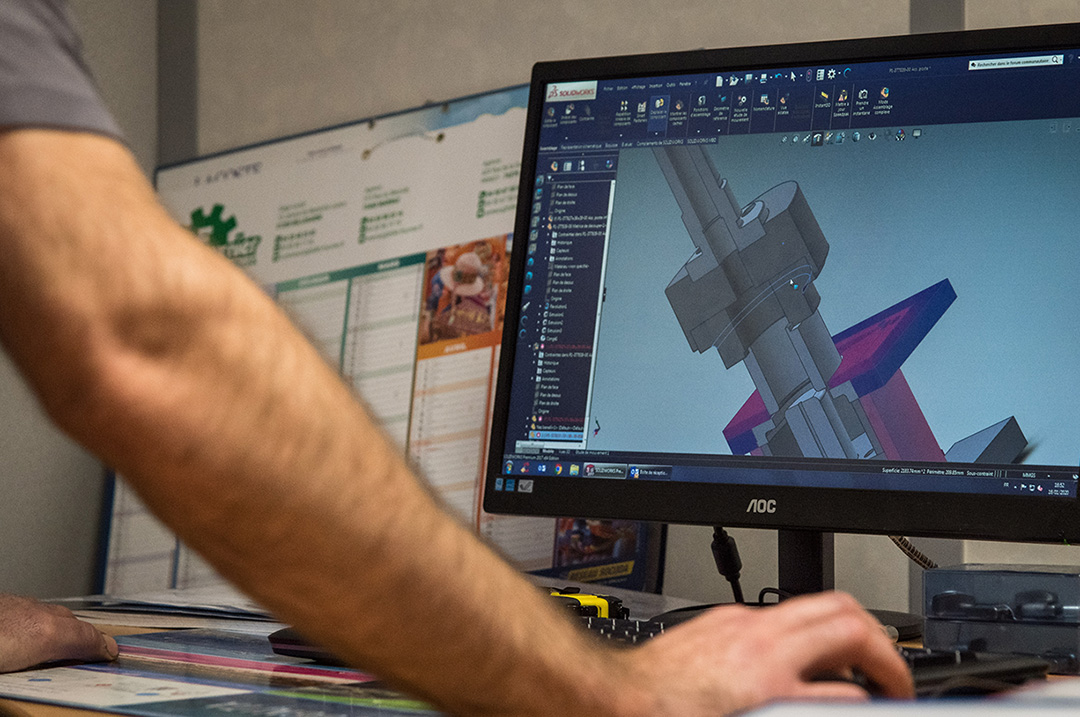

Engineering

In addition to the efficiency and adaptability of our machinery and to the professionalism of our teams, Emprotec’s strength lies in accompanying each step of your project.

Our R&D department, working closely with the tooling workshop, accompanies you from the design stage of your parts. The clear objective is to draw up specifications adapted to the technology of deep drawing on transfer press whilst taking into account the functional constraints of your parts to achieve maximum productivity.

Once this stage has been given approval, our tool-makers create the tooling. Depending on the type of production and the final use of your product, we can create prototypes and pre-production runs to ensure that everything is compatible before starting mass-production.

Capitalising on feedback from several decades, we are able to bring you effective advice and experience in design.

Key figures

million

million

presses

from 60 to 225 tonnes

tonnes

Our References

Would you like

to learn more?

Your trusted partner in deep drawing, Emprotec supplies you with high quality technical parts, bringing together expertise, innovation and meeting clients’ demands.

Parc d’activités Alpespace

401 Voie Galilée

73800 Sainte-Hélène-du-Lac

France

Regional Support: